Automotive mirrors may soon be a thing of the past.

Experts recommend that you check your mirrors every five seconds when driving—all three mirrors, rearview and both side views. That’s twelve times per minute, sixty times every five minutes. And that doesn’t even count the times when you’re changing lanes, merging into traffic, or slowing down.

Clearly, mirrors are critical to automotive safety.

Simple, inexpensive, and reliable, optical mirrors (the kind that rely on reflected light) have been used in cars for over 100 years. And during that time, they haven’t changed much. In fact, other than certain enhancements such as automatic dimming and other changes to size and shape, optical mirrors have been one of the few vehicle technologies that haven’t fundamentally changed as cars have become more and more complex.

So why change now?

Optical mirrors, while elegantly simple, have fundamental limitations. Because they rely on reflected light, they produce glare and are less effective at night. The field of view that they reproduce is inherently limited. Their placement creates blind spots and affects vehicle aerodynamics (wing-shaped side-view mirrors create enough drag to significantly reduce fuel economy).

But is there a better alternative?

Removing mirrors and replacing them with high-resolution sensing cameras and displays is an increasingly popular option. Instead of a rearview mirror, a small camera is placed on the back of the vehicle, above the rear window, while the video feed is sent to an in-cabin display for viewing. The two side-view mirrors receive the same treatment: they are replaced with low-profile cameras, one on each side, with the resulting video feed sent to two in-cabin displays.

This combination of camera and display is typically referred to as an “electronic mirror” or a “camera monitoring system (CMS).” At Ambarella, we believe that electronic mirrors are on the verge of revolutionizing the way drivers monitor the road.

The advantages to electronic mirrors are clear:

- Cameras offer full visibility for vehicles without optical rear-view mirrors (e.g., commercial trucks, moving vans), as well as passenger vehicles with loaded backseats.

- Smart features such as blindspot detection make lane-changes safer.

- Low-light processing improves night vision.

- High dynamic range (HDR) processing removes glare (e.g., from headlights).

- Our LED flicker mitigation (LFM) feature eliminates potentially distracting pulsing effects from environmental LED light sources.

- Cameras produce negligible drag on the vehicle exterior.

- Camera lenses offer a wider field of view.

- Electronic image stabilization (EIS) virtually eliminates vibration, creating a steadier picture.

We can even “stitch” the three views together via software to create a single, unified view of the environment.

So, what are the technological challenges to implementing electronic mirrors?

Keeping the camera lenses clean is one challenge (we’ve developed a dirt-detection function that helps significantly). The more important challenge is ensuring reliability. An optical mirror, for all its limitations, always functions as expected. An electronic mirror must do the same to be effective. It can’t go dark, and it can’t freeze up, displaying a static image. It must do what its analog counterpart has done for over a century—perform the job dependably, without fanfare.

“For an electronic mirror to be effective, it must do what its analog counterpart has done for over a century—perform the job as expected, without fanfare or failure.”

Meeting this high standard means introducing multiple failsafe mechanisms into these systems and conducting extensive testing before release. Which is one of the many projects we’re working on at Ambarella today.

How to make a smarter mirror.

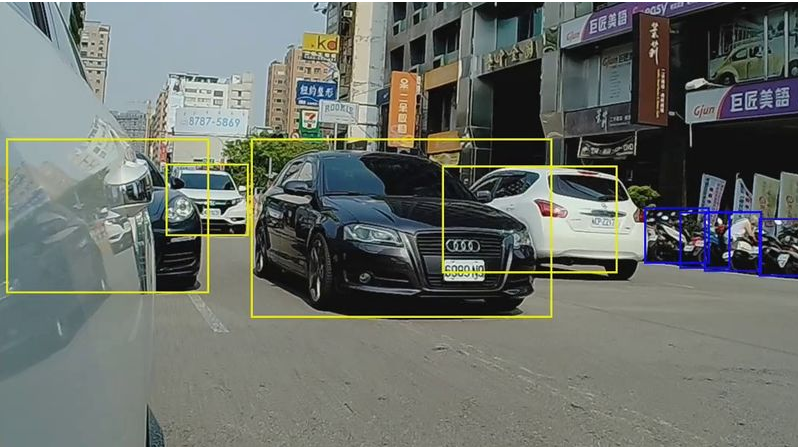

Our engineers take to the streets and gather data—a lot of data—and make adjustments on the fly, fine-tuning the system using real-world scenarios.

While ensuring the highest image quality is always a priority, our focus during testing is typically on computer vision-based safety features.

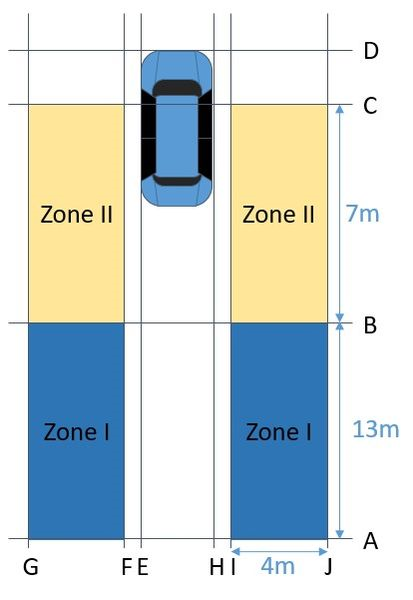

Our blind-spot detection (BSD) feature is one example. This smart feature is designed to detect objects that enter the area directly adjacent to the vehicle (an area considered un-viewable using a traditional optical mirror). Our smart cameras have the ability to understand the dimensions of the area and not only detect when something enters the space, but actually distinguish between vehicles, cyclists, and even people.

So, why Ambarella?

We’re not the only chipmaker who specializes in intelligent electronic mirror technology. So why are our solutions successful in the marketplace?

- ISP: Our solution excels in difficult lighting conditions, such as night time, high-glare, or shadowy environments. This is thanks to our ISP, which has been refined over the course of nearly twenty years in automotive, security, and consumer applications.

- High frame rates: Our BSD feature works effectively at high frame rates, which are required in order to run DNN algorithms using powerful CV engines.

- Fast boot: Our computer vision SoCs boot-up extremely quickly (no one wants to wait even one or two seconds for their mirror to become active).

- Low latency: The camera processing in our electronic mirrors is virtually instantaneous. This ensures that the driver will always see a current image, and that the BSD detection feature will be quick enough to deliver reliable warnings.

- High resolution: The selected camera configuration covers a wide field of view (FOV) when required, yet simultaneously provides a high enough resolution for BSD detection to work when cars approach at high rates of speed. This is critical for an electronic mirror solution.

- Low power: The electronic mirror setup is highly effective without requiring excess power.

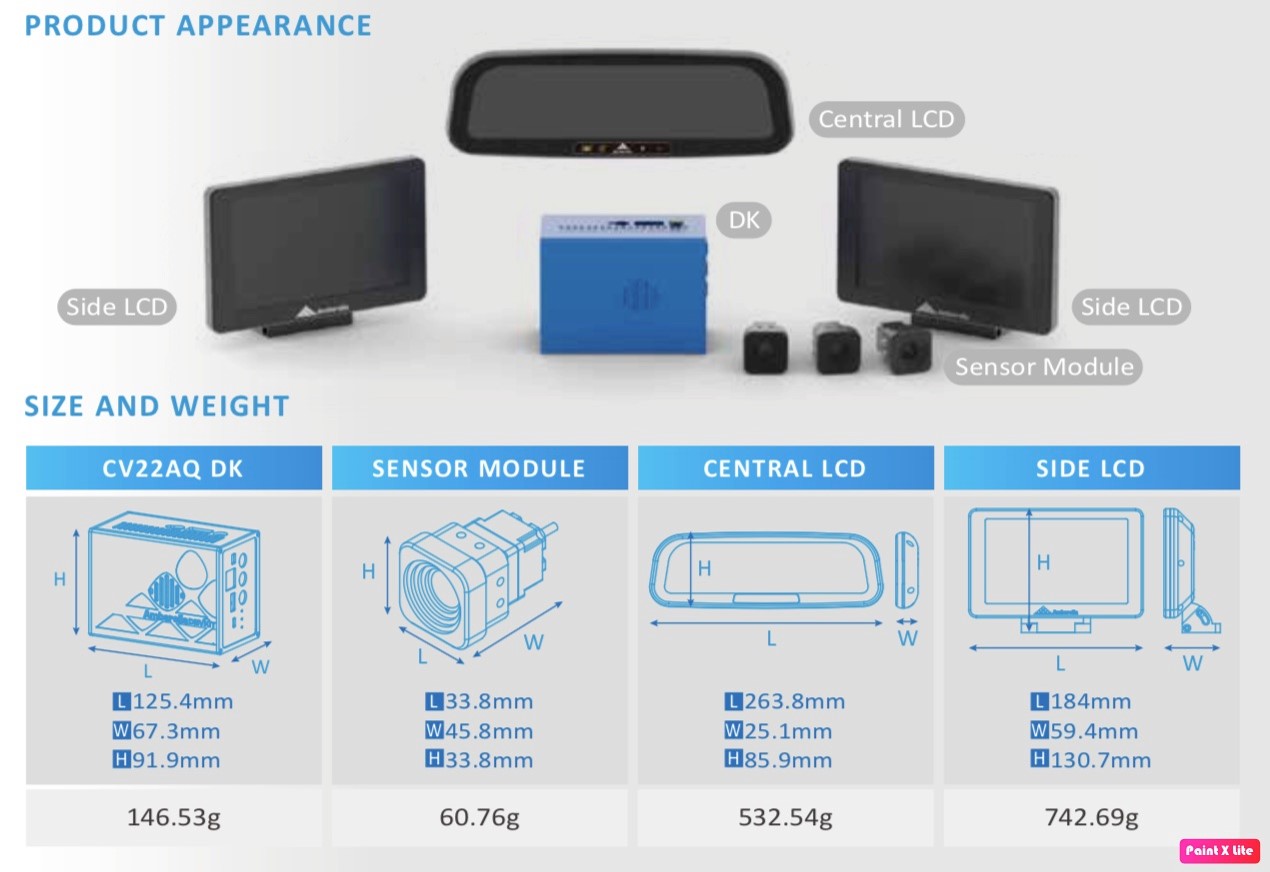

Below is a system diagram showing one possible configuration using our CV22 automotive SoC (click here for more information on CV22).

For additional information on our electronic mirror applications, please contact us.